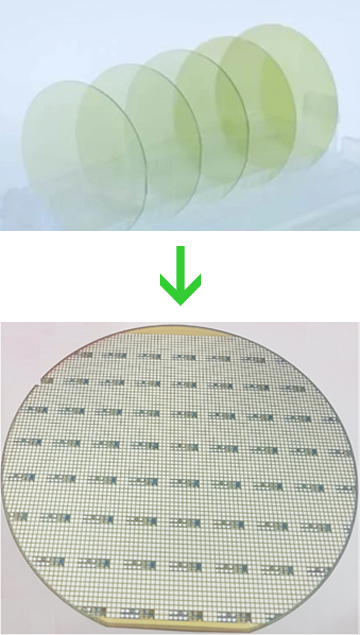

WAFER Service

6 Inch SiC Wafer Service

Capability

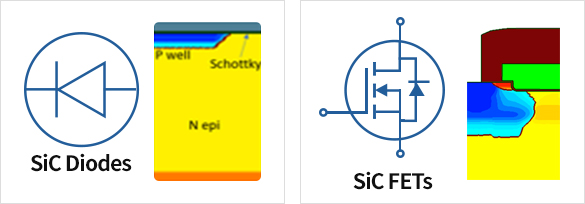

Clean Class : Class 1Custom development and manufacturing for SiC Diode and MOSFET

Front-end processing

Photolithography : Resolution 0.4um Trench depth : 3um without micro trench High Temperature Anneal/Oxidation: 2000C/1500C High Temperature implant: 600C

Thinning and back metallization processing

Thinning : 200um Laser anneal : SilicidationSiC Process Capabilities

SiC Process Capabilities

High Temperature Implant ( 600℃ )

Available Tools for SiC Processing

Photolithography